With a strong focus on quality control and technological optimization of composite curing processes we provide integrated solutions for evaluation of processes and tools.

Therefore we use our flexible software CuringDesk for automated process data analysis.

In addition we provide specialized measurements in the following fields

Thermo-profiles

Every mould and all composite material system have their own thermal specifics. Tool design, thermal conductivity, melting energies, exothermic reaction, etc. set high requirements on the thermo-profiles for the inital commissioning of the mould-part system.

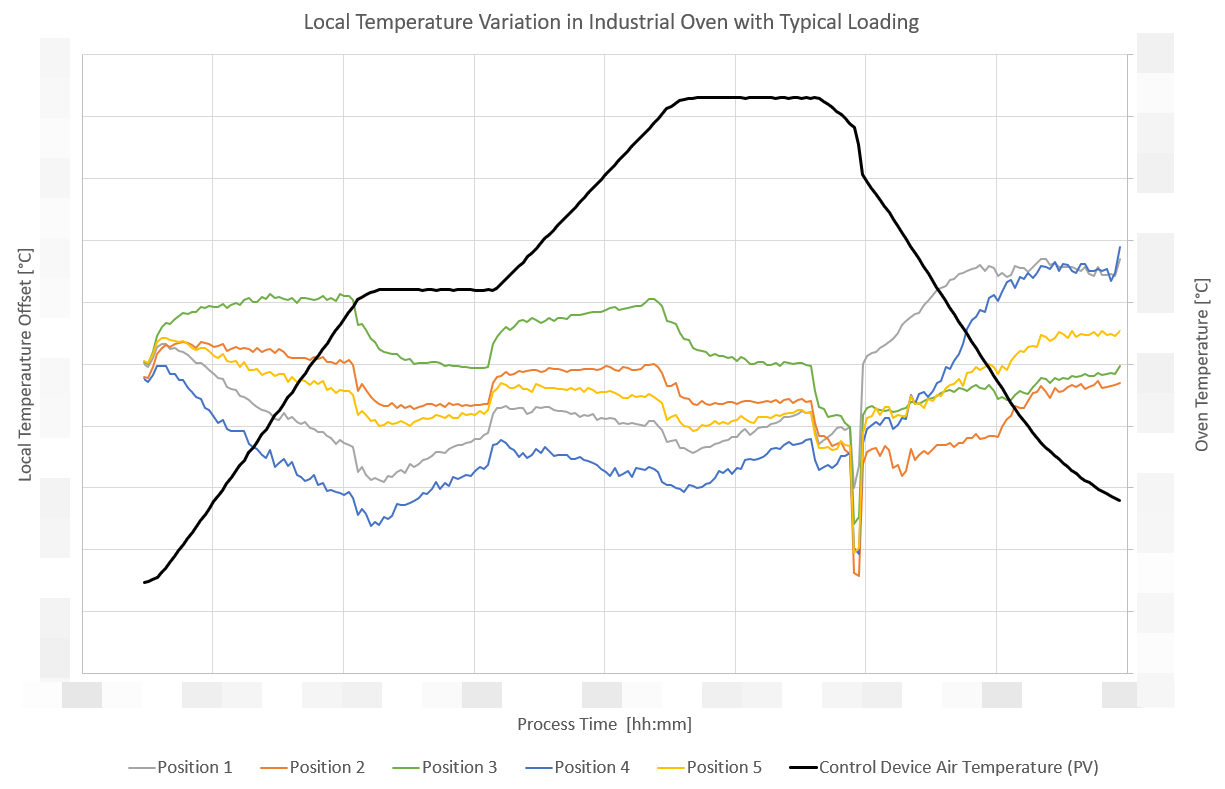

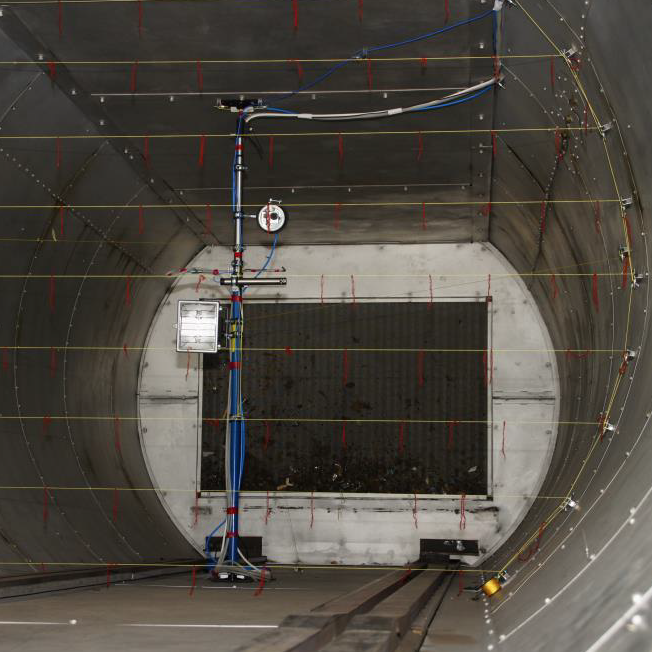

Temperature uniformity

A uniform distribution of the temperature inside the heat treatment chamber is essential for a predictable process result. Local effects of doors, openings, insulation inequalities, local air flow recirculations, etc. have to be considered.

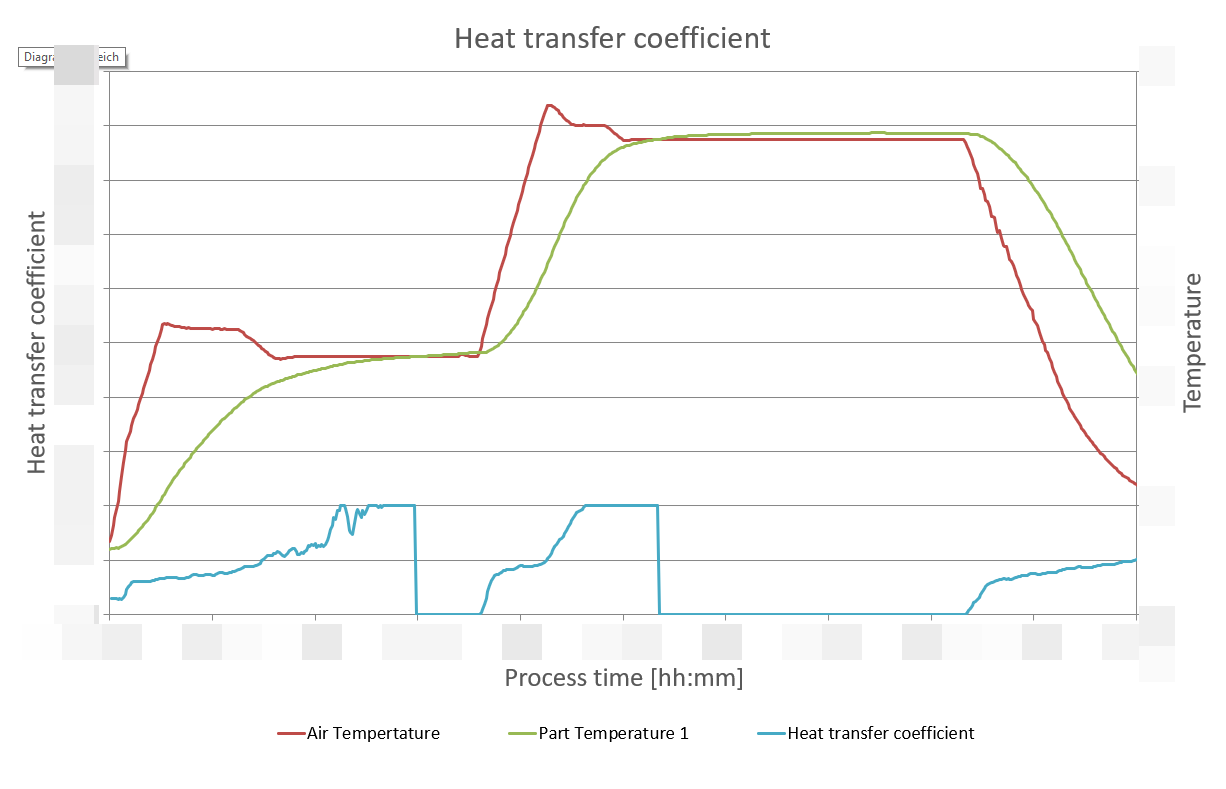

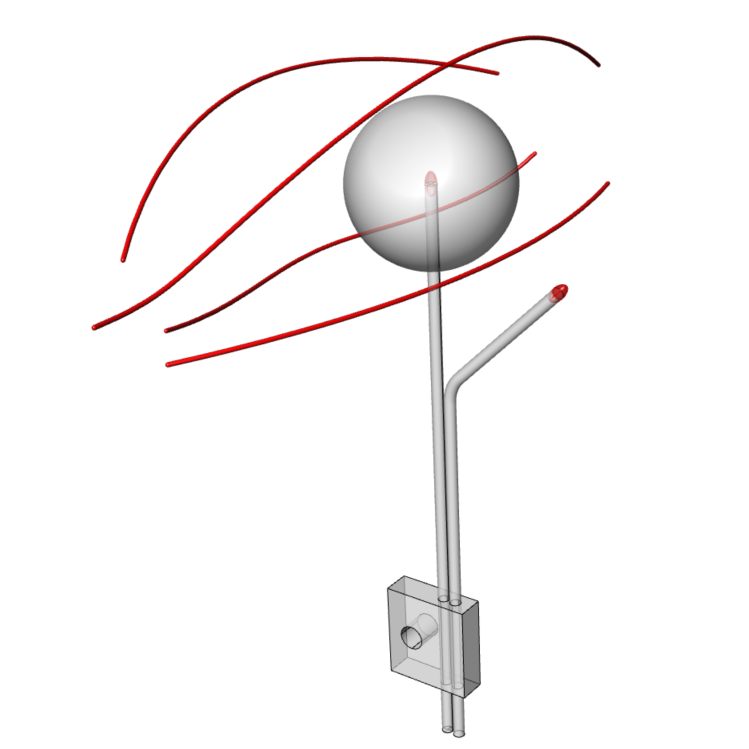

Heat transfer

The transfer of the heat energy from the surrounding atmosphere into the mould and part depends strongly on the local temperature difference, pressure and the local wind speed.

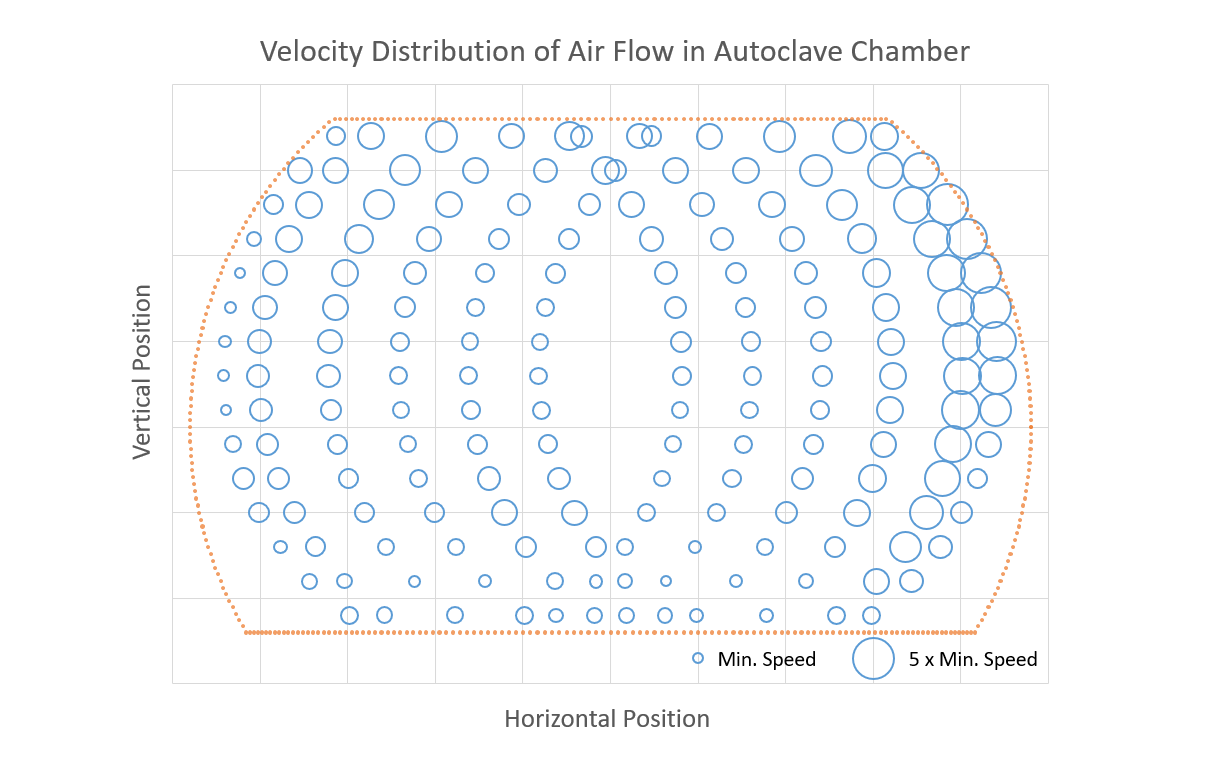

Air flow

The air flow behaviour inside the oven or autoclave is highly complex. It is influenced by the system design and the loading which is applied to the chamber.