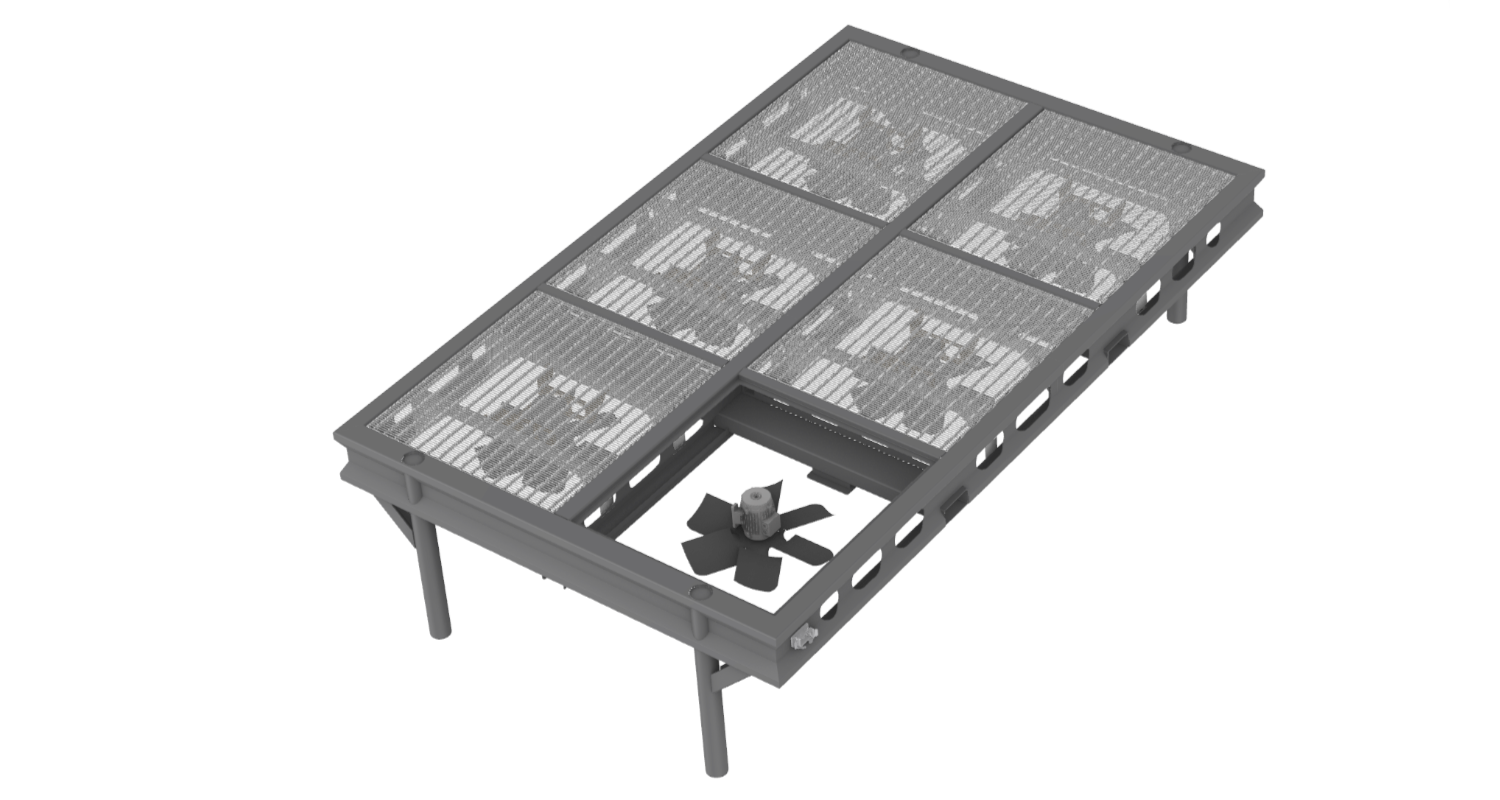

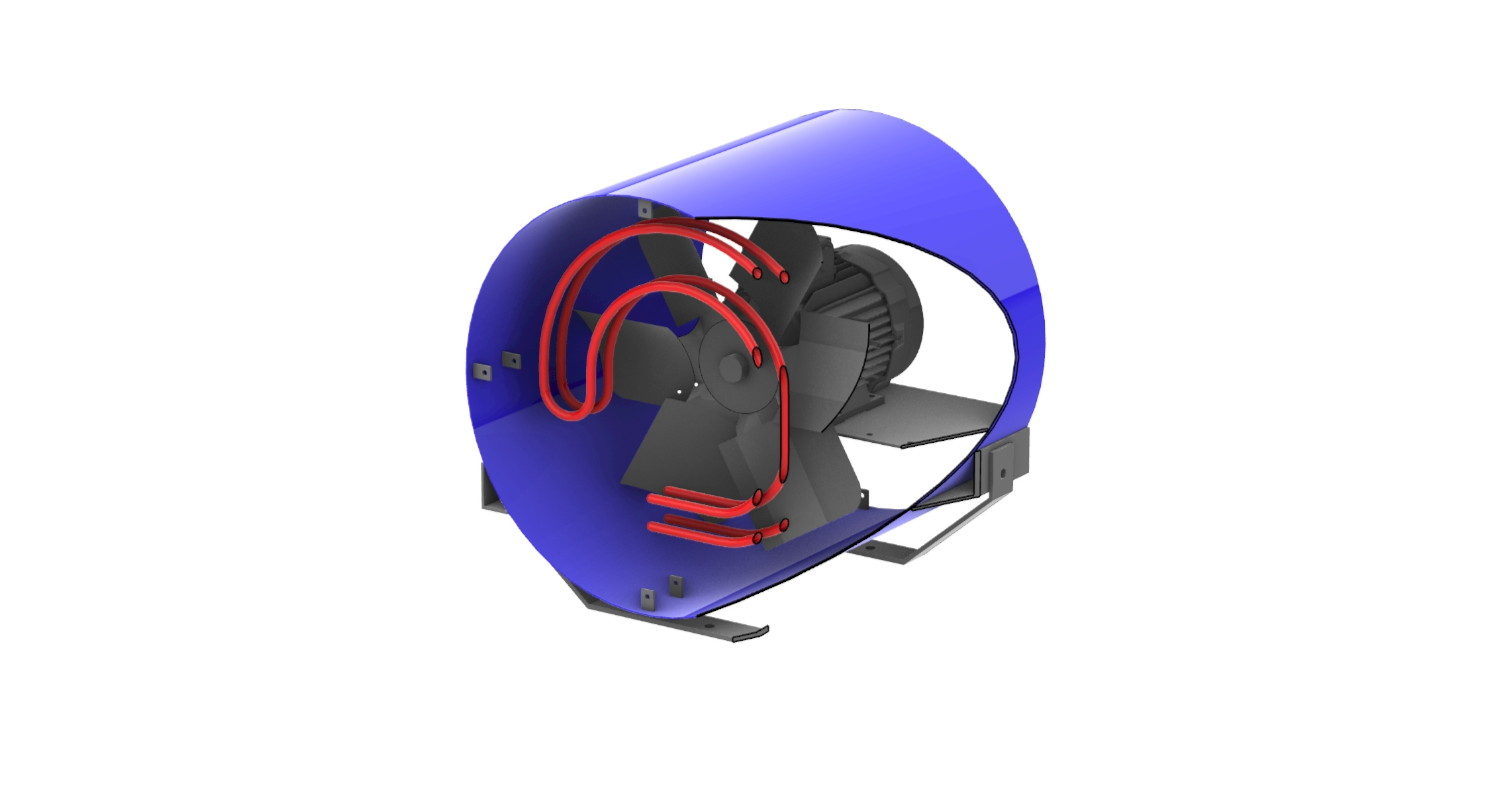

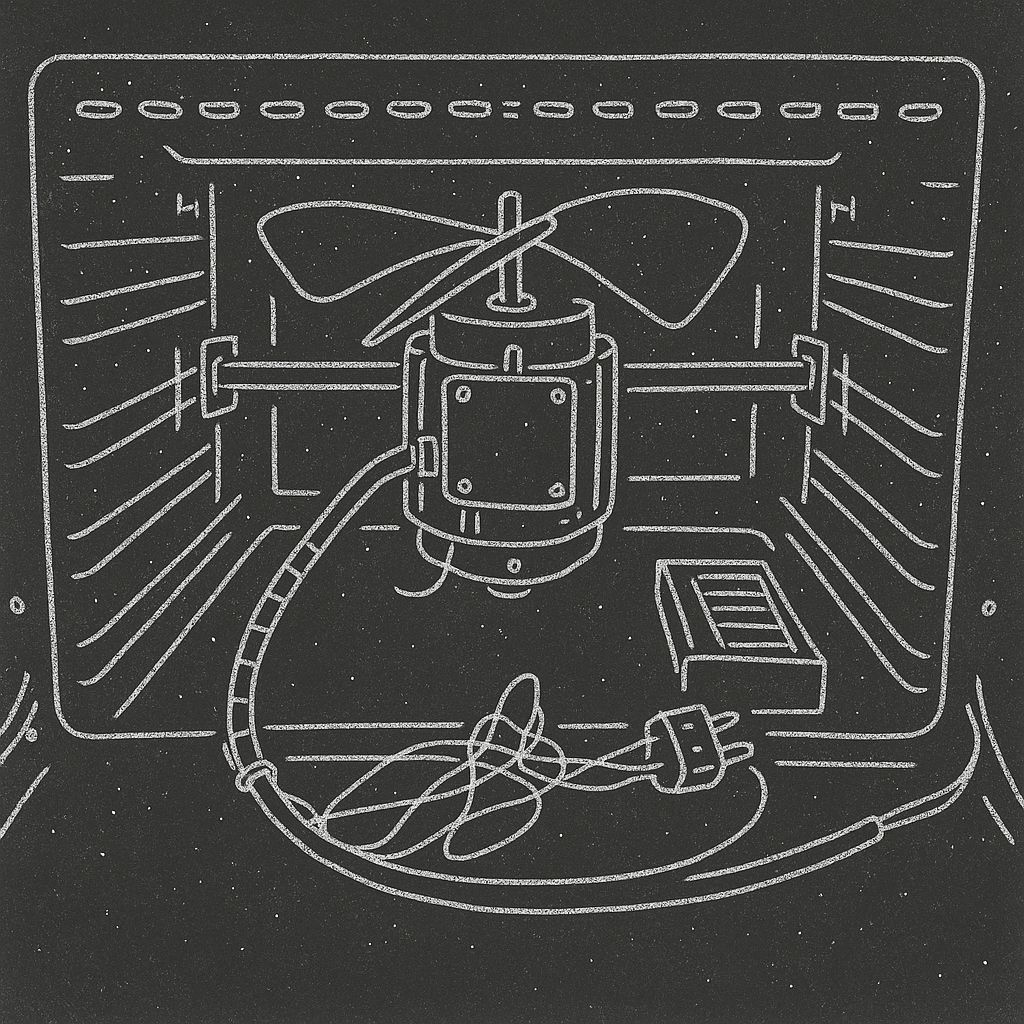

Concept, Design and Testing

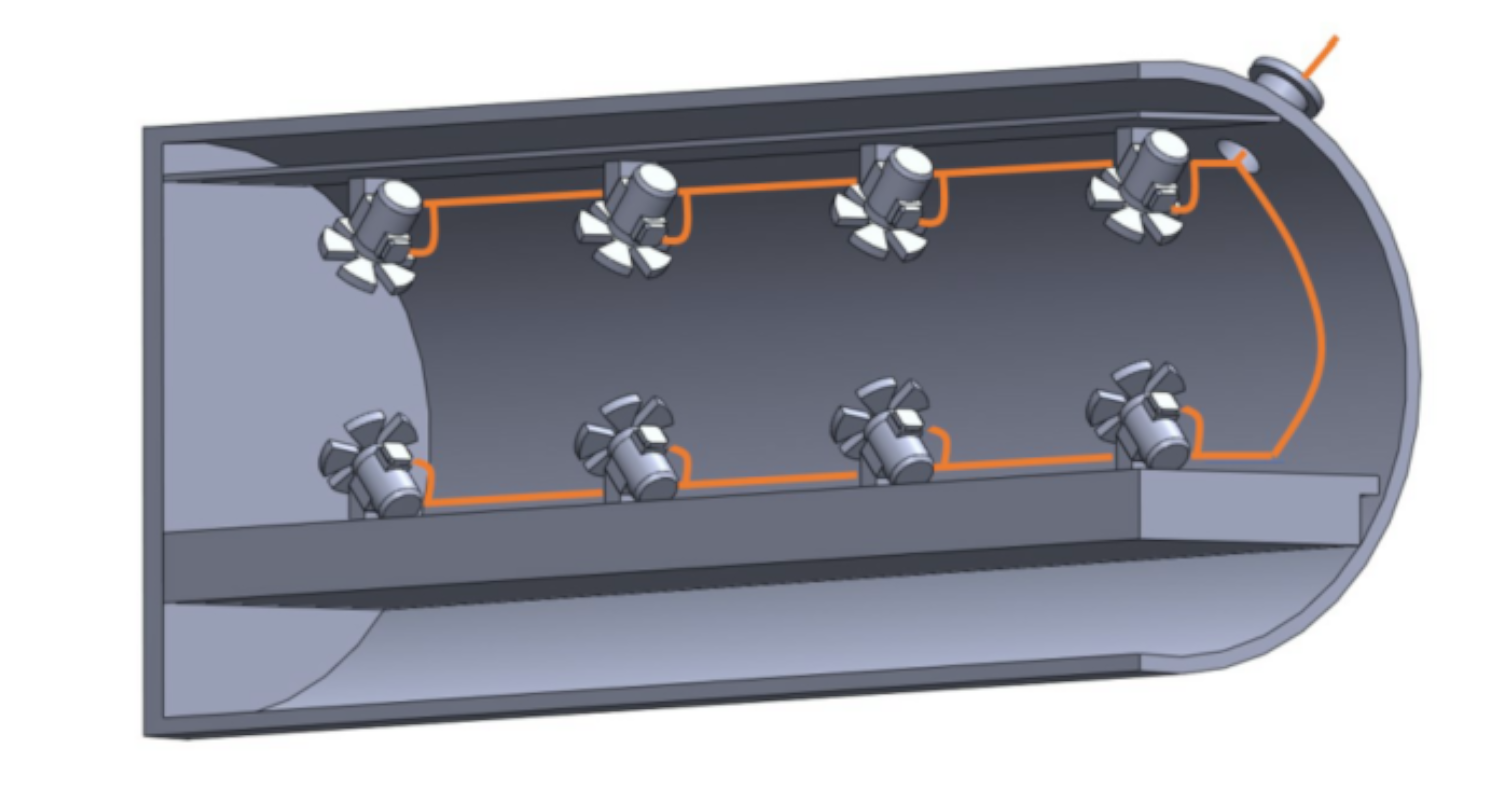

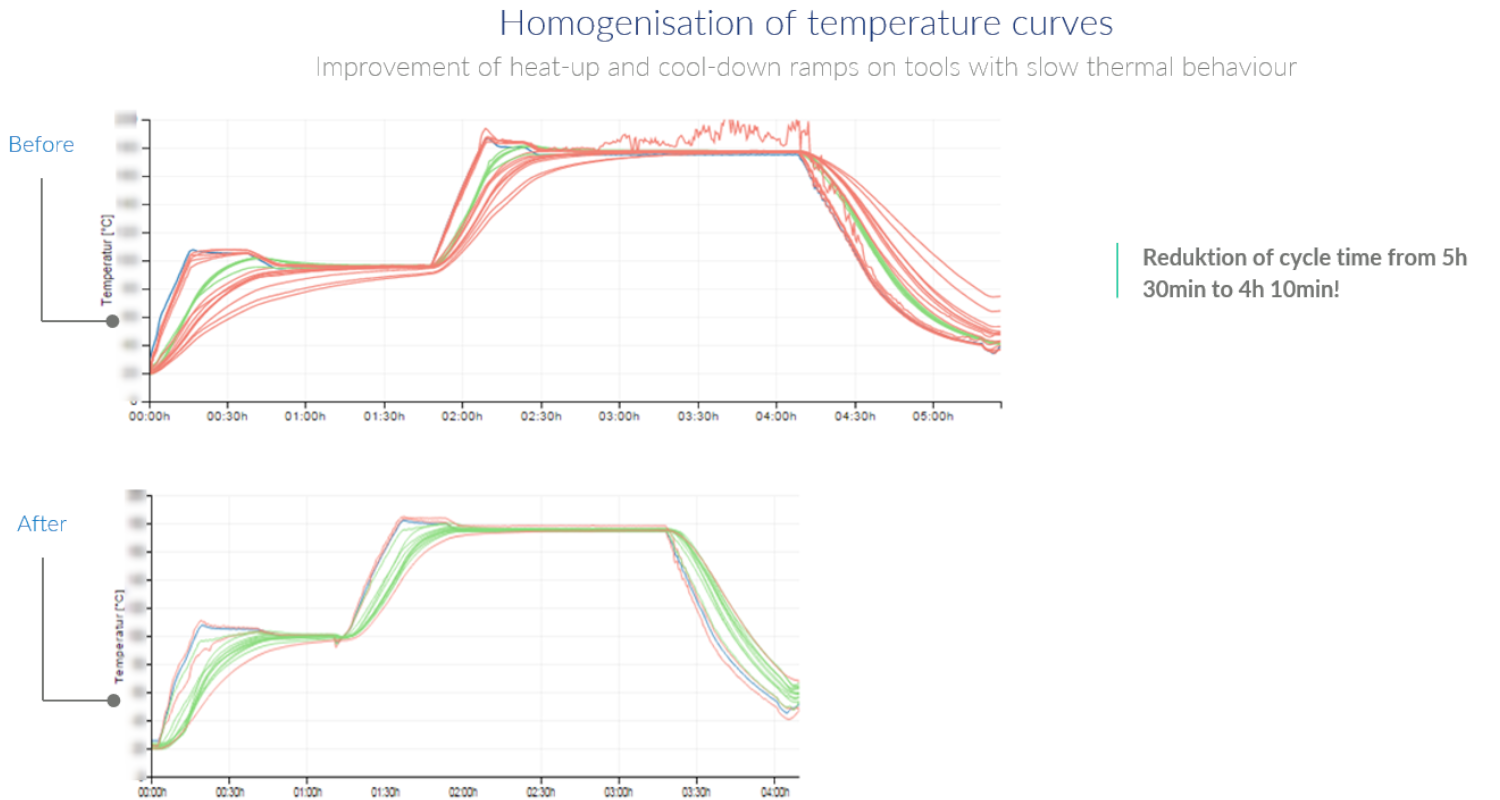

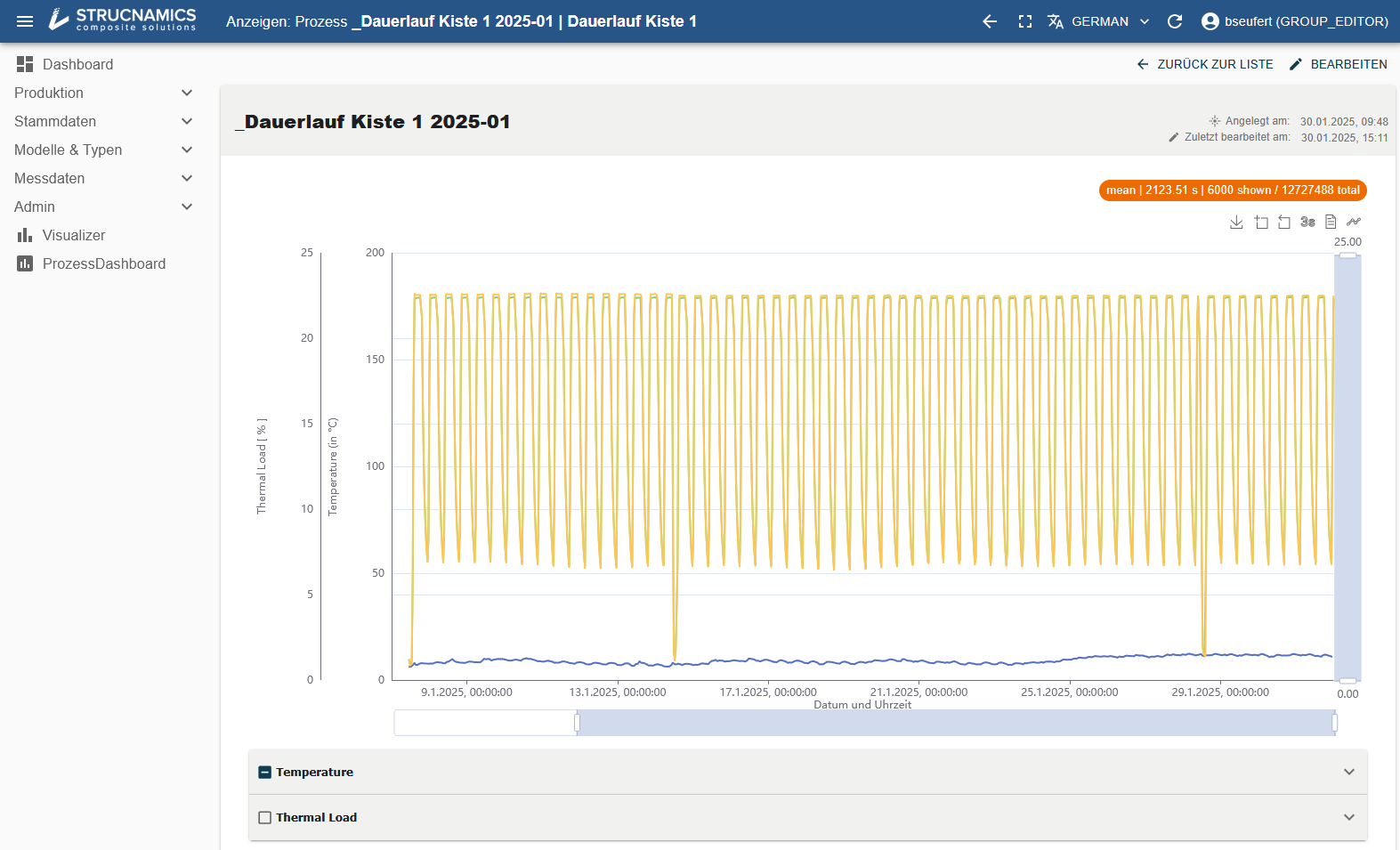

In view of the harsh environmental conditions, various drives were tested and developed. Long-term tests over several months revealed with "brutal honesty" which concepts and designs could withstand use in serial production.