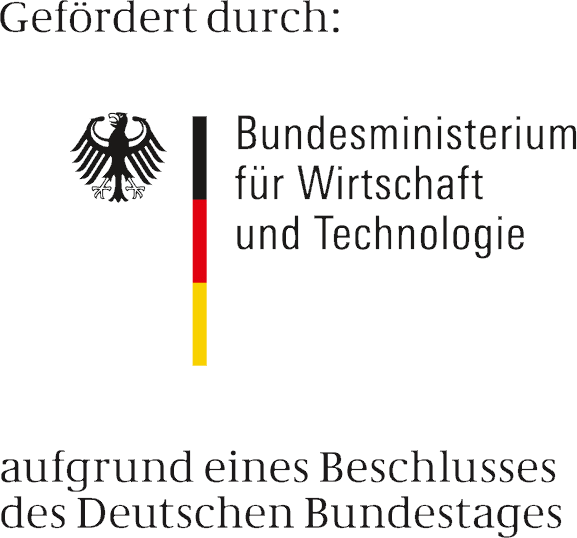

The Challenge …

Information flow without an integrated database

Comprehensive information management during the curing process provides an enormous opportunity for process improvements.

Composite manufacturers must operate with the idea of continuous improvement in order to increase productivity and to improve product quality. However, increasing productivity of the curing process cannot compromise the highly developed quality management systems that are required in the composites manufacturing.

Additionally, the curing process involves a significant amount of data management, which makes it difficult to keep all process participants informed and synchronized.

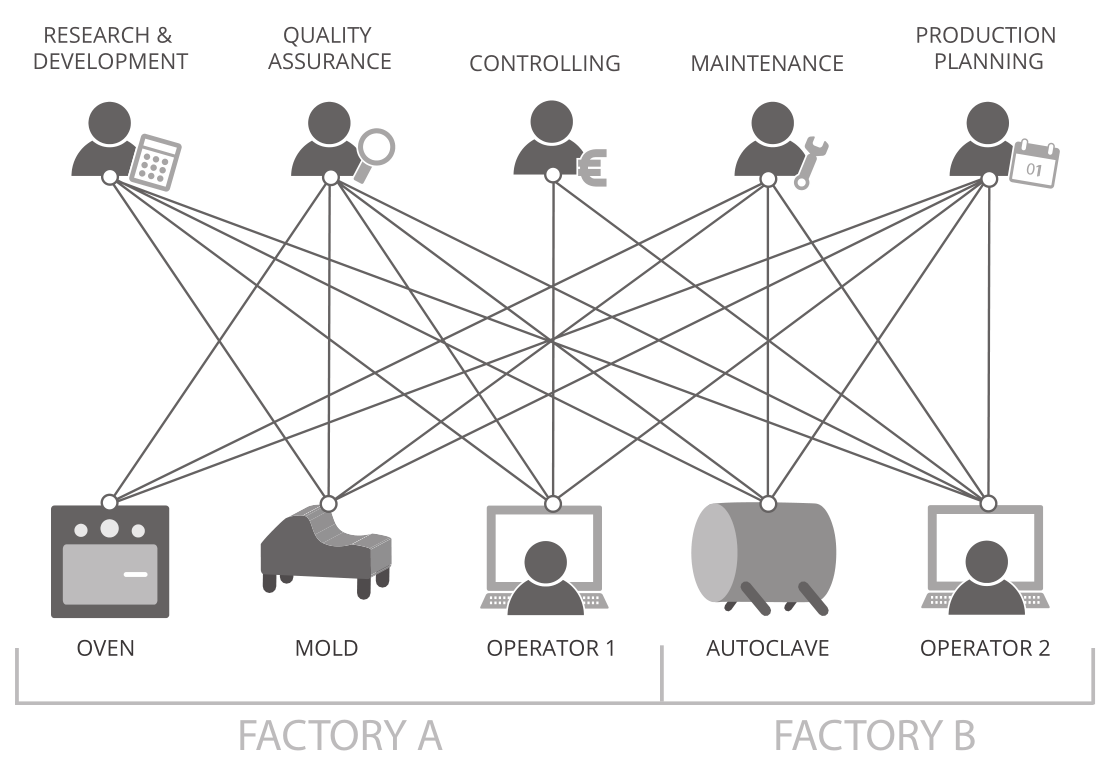

…Our Solution

CuringDesk manages the flow of information

CuringDesk manages the complex flow of information to provide a common and up-to-date information basis to all users.

CuringDesk is a software which provides solutions for the complicated quality management challenges that are associated with hardening and curing processes. Our solution adds value to the quality management by automating data collection and analysis and collaboration of shop-floor, engineering, planning and controlling departments.

CuringDesk enhances a manufacturer’s competitive advantage through its innovative ideas and its information-based solutions.

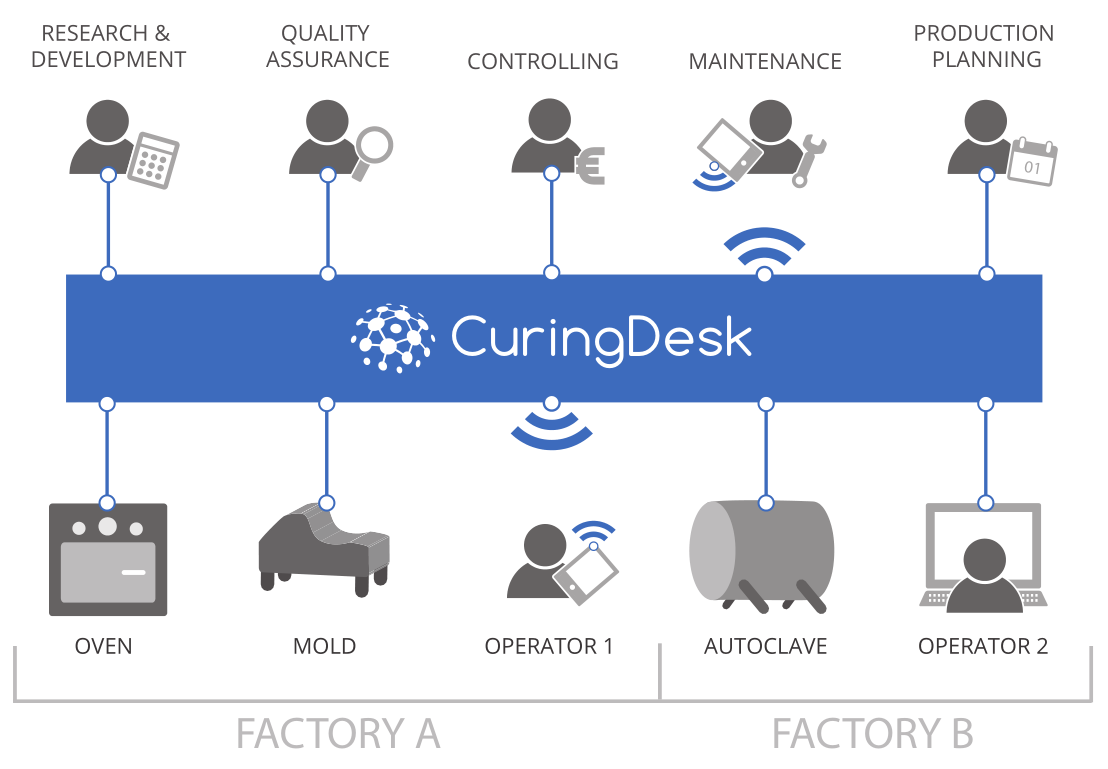

How it works

Information feed with the selectable CuringDesk modules

CuringDesk provides automated and standardized data processing and analysis with customized extension tools.

Quality by control

Various data sources like work orders, set-curves, curve limits and measurement data are unified in the database of CuringDesk. All data is available on the intranet (PC, tablet, etc.) via the browser. The administration of process set parameters and evaluation limits is centralized and version controlled.

- Speeds up check and release workflow

- Supports quality management systems, e.g. ISO 9100

- Ensures proper configuration management and prevents errors

Efficiency by transparency

CuringDesk provides a comprehensive overview of all processes, tools, sensors and parameters. Automated data analysis and reporting increases the efficiency of monitoring curing processes.

- Provides statistics for technological correlations, key figures and process details

- Reveals hidden optimization opportunities

- Allows easy data exporting to Excel

Cost reduction by automation

Automated analysis enables reporting, overviews and comparative studies. CuringDesk offers a simplified way to monitor curing processes.

- Reduces manual effort through automated analysis

- Reduces cycle time of curing devices (autoclaves, ovens, heated molds)

- Provides an early recognition of process trends, thus avoiding non-conformities and reducing rework or scrap rates

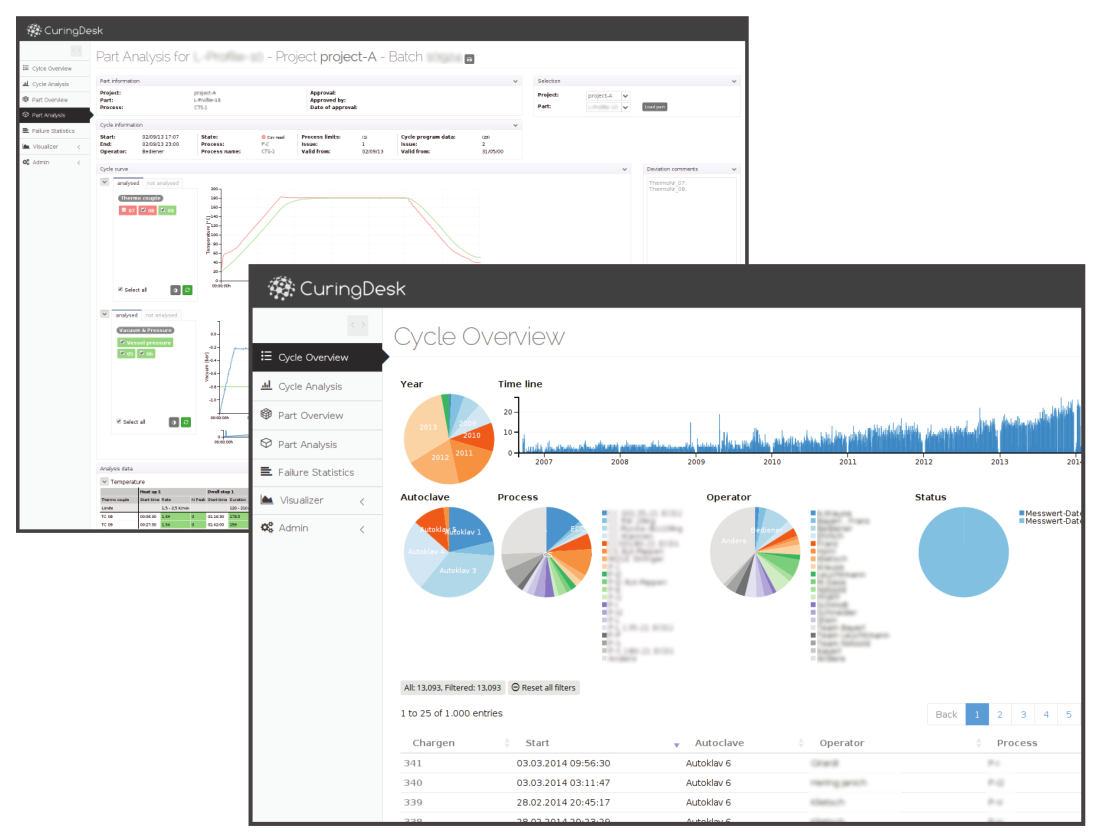

Screenshots

The CuringDesk user interface provides graphical information that is clear, comprehensible, and effective.